engine oil Ram 1500 2014 Get to Know Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2014, Model line: 1500, Model: Ram 1500 2014Pages: 252, PDF Size: 6.74 MB

Page 10 of 252

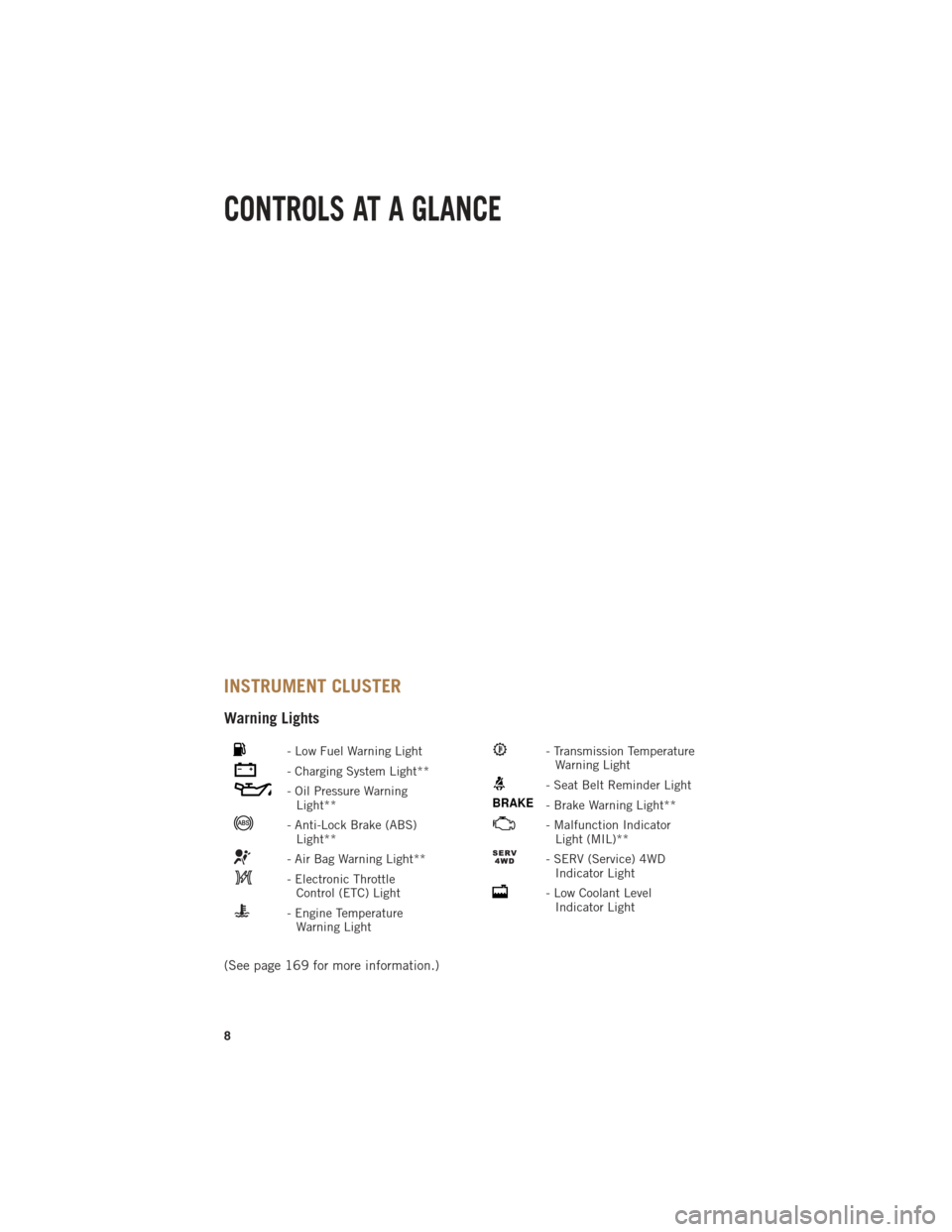

INSTRUMENT CLUSTER

Warning Lights

- Low Fuel Warning Light

- Charging System Light**

- Oil Pressure WarningLight**

- Anti-Lock Brake (ABS)Light**

- Air Bag Warning Light**

- Electronic ThrottleControl (ETC) Light

- Engine TemperatureWarning Light

- Transmission TemperatureWarning Light

- Seat Belt Reminder Light

BRAKE- Brake Warning Light**

- Malfunction IndicatorLight (MIL)**

- SERV (Service) 4WDIndicator Light

- Low Coolant LevelIndicator Light

(See page 169 for more information.)

CONTROLS AT A GLANCE

8

Page 34 of 252

ENGINE BREAK-IN RECOMMENDATIONS

A long break-in period is not required for the engine and drivetrain (transmission and

axle) in your vehicle.

Drive moderately during the first 300 miles (500 km). After the initial 60 miles

(100 km), speeds up to 50 or 55 mph (80 or 90 km/h) are desirable.

While cruising, brief full-throttle acceleration within the limits of local traffic laws

contributes to a good break-in. Wide-open throttle acceleration in low gear can be

detrimental and should be avoided.

The engine oil installed in the engine at the factory is a high-quality energy

conserving type lubricant. Oil changes should be consistent with anticipated climate

conditions under which vehicle operations will occur. For the recommended viscosity

and quality grades, refer to “Maintaining Your Vehicle.”

NOTE:

A new engine may consume some oil during its first few thousand miles (kilometers)

of operation. This should be considered a normal part of the break-in and not

interpreted as an indication of an engine problem or malfunction.

CAUTION!

Never use Non-Detergent Oil or Straight Mineral Oil in the engine or damage may

result.

DIESEL ENGINE BREAK-IN RECOMMENDATIONS

• For 3.0L diesel engine break-in recommendations, refer to Diesel Engine Break-InRecommendations on pg. 145

• For 6.7L Cummins diesel engine break-in recommendations, refer to Diesel Engine Break-In Recommendations on pg. 155

OPERATING YOUR VEHICLE

32

Page 120 of 252

EVIC Reconfigurable Screen Setup

The following settings allow you to change what information is displayed in the

instrument cluster as well as the location that information is displayed.

Digital Speedometer

• Press and release the UP or DOWN arrow button until the Digital display icon ishighlighted in the EVIC. Press and release the RIGHT arrow button to change the

display between km/h and mph.

Vehicle Info (Customer Information Features)

• Press and release the UP or DOWN button until the Vehicle Info icon is highlightedin the EVIC Display. Press and release the RIGHT or LEFT to scroll through the

following Vehicle Info submenus:• Tire Pressure Monitor System

• Air Suspension — If Equipped

• Coolant Temperature (Diesel Only)

• Transmission Temperature (ATX Only)

• Oil Temperature

• Oil Pressure

• Oil Life

• Fuel Filter Life (Diesel Only)

• Battery Voltage

• Exhaust Brake (Diesel Only)

• Turbo Boost (Diesel Only)

• Gauge Summary

• Coolant Temperature (Diesel Only)

• Transmission Temperature (ATX Only)

• Oil Temperature

• Oil Pressure

• Engine Hours

Trip A

• Press and release the UP or DOWN arrow button until the Trip A icon is highlighted in the EVIC. Press and hold the RIGHT arrow button to reset the Trip A information.

Trip B

• Press and release the UP or DOWN arrow button until the Trip B icon is highlightedin the EVIC. Press and hold the RIGHT arrow button to reset the Trip B information.

ELECTRONICS

118

Page 147 of 252

DIESEL ENGINE BREAK-IN RECOMMENDATIONS

• The 3.0 turbocharged diesel engine does not require a break-in period due to itsconstruction. Normal operation is allowed, providing the following recommenda-

tions are followed:• Warm up the engine before placing it under load.

• Do not operate the engine at idle for prolonged periods.

• Use the appropriate transmission gear to prevent engine lugging.

• Observe vehicle oil pressure and temperature indicators.

• Check the coolant and oil levels frequently.

• Vary throttle position at highway speeds when carrying or towing significant

weight.

NOTE:

Light duty operation such as light trailer towing or no load operation will extend the

time before the engine is at full efficiency. Reduced fuel economy and power may be

seen at this time.

• The engine oil installed in the engine at the factory is a high-quality energy conserving type lubricant. Oil changes should be consistent with anticipated

climate conditions under which vehicle operations will occur. The recommended

viscosity and quality grades are shown under “FLUIDS AND CAPACITIES”, under

“MAINTAINING YOUR VEHICLE” in this User Guide. NON-DETERGENT OR

STRAIGHT MINERAL OILS MUST NEVER BE USED.

DIESEL ENGINE STARTING PROCEDURES

Normal Starting Procedure

1. Apply the parking brake.

2. Ensure the shift lever is in the PARK position.

3. Press and hold the brake pedal while pressing the ENGINE START/STOP button

once.

4. The system will take over and attempt to start the vehicle. If the vehicle fails to start, the starter will disengage automatically after 30 seconds.

5. If you wish to stop the cranking of the engine prior to the engine starting, press the button again.

6. Check that the oil pressure warning light has turned off.

7. Release the parking brake.

1500 3.0L DIESEL

145

Page 149 of 252

DIESEL FUEL FILTER/WATER SEPARATOR

Draining Fuel/Water Separator

•If the “Water in Fuel” indicator lightis illuminated and an audible chime is

heard five times, you should stop the engine and drain the water from the separator.

• The drain plug is located on the bottom of the Fuel Filter and Water Separator assembly which is located above the rear axle next to the fuel tank.

• Loosen the drain plug (located on the bottom filter assembly) then turn the ignition switch to the ON/RUN position to allow any accumulated water to drain.

• When clean fuel is visible, close the drain and switch the ignition to the OFF position.

• Refer to the Diesel Supplement on the DVD for further details.

Fuel Filter Replacement

1. Ensure engine is turned off.

2. Place drain pan under the fuel filter assembly.

3. Open the water drain valve, and let any accumulated water drain.

4. Close the water drain valve.

5. Remove bottom cover using a strap wrench. Rotate counterclockwise for removal. Remove the used o-ring and discard it.

6. Remove the used filter cartridge from the housing and dispose of according to your local regulations.

7. Wipe the sealing surfaces of the lid and housing clean.

8. Install new o-ring back into ring groove on the filter housing and lubricate with clean engine oil.

NOTE:

The WIF (Water In Fuel) sensor is re-usable. Service kit comes with new o-ring for

filter canister and WIF (Water In Fuel) sensor.

CAUTION!

•Diesel fuel will damage blacktop paving surfaces. Drain the filter into an appro-

priate container.

•Do not prefill the fuel filter when installing a new fuel filter. There is a possibility

debris could be introduced into the fuel filter during this action. It is best to install

the filter dry and allow the in-tank lift pump to prime the fuel system.

• If the “Water In Fuel Indicator Light” remains on, DO NOT START the engine before you drain water from the fuel filter to avoid engine damage.

1500 3.0L DIESEL

147

Page 157 of 252

DIESEL ENGINE BREAK-IN RECOMMENDATIONS

The Cummins®turbocharged diesel engine does not require a break-in period due to

its construction. Normal operation is allowed, providing the following recommenda-

tions are followed:

• Warm up the engine before placing it under load.

• Do not operate the engine at idle for prolonged periods.

• Use the appropriate transmission gear to prevent engine lugging.

• Observe vehicle oil pressure and temperature indicators.

• Check the coolant and oil levels frequently.

•

Vary throttle position at highway speeds when carrying or towing significant weight.

NOTE:

Light duty operation such as light trailer towing or no load operation will extend the

time before the engine is at full efficiency. Reduced fuel economy and power may be

seen at this time.

Because of the construction of the Cummins

®turbocharged diesel engine, engine

run-in is enhanced by loaded operating conditions which allow the engine parts to

achieve final finish and fit during the first 6,000 miles (10 000 km).

DIESEL ENGINE STARTING PROCEDURES

Engine Block Heater

For ambient temperatures below 0°F (-18°C), engine block heater usage is recom-

mended.

For ambient temperatures below –20°F (-29°C), engine block heater usage is required.

The engine block heater cord is routed under the hood to the right side and can be

located just behind the grille near the headlamp.

Connect the heater cord to a ground-fault interrupter protected 110–115 volt AC

electrical outlet with a grounded, three-wire extension cord.

NOTE:

The block heater will require 110 volts AC and 6.5 amps to activate the heater element.

The block heater must be plugged in at least one hour to have an adequate warming

effect on the coolant.

6.7L CUMMINS® DIESEL

155

Page 158 of 252

Water In Fuel Message

If a Water In Fuel message orindicator appears in the cluster and a chime sounds

five times, the fuel/water separator will need to be drained immediately to prevent

engine damage.

Refer to “Draining Fuel Water Separator” in this guide for draining instructions or see

your dealer.

Cold Start Procedure

• Turn the ignition switch to the ON position. If the Wait To Startlight appears

in the cluster, wait for the light to turn off before starting.

• In extremely cold weather below 0°F (-18°C) it may be beneficial to cycle the manifold heaters twice before attempting to start the engine. This can be

accomplished by turning the ignition OFF for at least five seconds and then back

ON after the “Wait To Start Light” has turned off, but before the engine is started.

However, excessive cycling of the manifold heaters will result in damage to the

heater elements or reduced battery voltage.

Refer to the Owner's Manual Diesel Supplement on the DVD for further details.

Engine Idling

Avoid prolonged engine idling. Long periods of idling may be harmful to your engine

because combustion chamber temperatures can drop so low that the fuel may not

burn completely.

Incomplete combustion allows carbon and varnish to form on piston rings, engine

valves, and injector nozzles. Also, the unburned fuel can enter the crankcase,

diluting the oil and causing rapid wear to the engine.

If the engine is allowed to idle, under some conditions the idle speed may increase

to 900 RPM then return to normal idle speed. This is normal operation.

WARNING!

Remember to disconnect the cord before driving. Damage to the 110–115 volt

electrical cord could cause electrocution.

6.7L CUMMINS® DIESEL

156

Page 161 of 252

• Turn the drain valve (located on the side of the filter) counterclockwise 1/4 turn,then turn the ignition switch to the ON/RUN position to allow any accumulated

water to drain.

• When clean fuel is visible, close the drain and switch the ignition to OFF.

• Refer to the Diesel Supplement on the DVD for further details.

Fuel Filter Replacement

• With the engine off and a drain pan under the fuel filter drain hose, open the water drain valve 1/4 turn counterclockwise and completely drain fuel and water into the

approved container.

• Close the water drain valve and remove the lid using a socket or strap wrench; rotate counterclockwise for removal. Remove the used o-ring and discard it.

• Remove the used filter cartridge from the housing and dispose of according to your local regulations.

• Wipe clean the sealing surfaces of the lid and housing and install the new o-ring into ring groove on the filter housing and lubricate with clean engine oil.

• Install a new filter in the housing. Push down on the cartridge to ensure it is properly seated. Do not pre-fill the filter housing with fuel.

• Install the lid onto the housing and tighten to 22.5 ft lbs (30.5 N·m). Do not overtighten the lid.

• Start the engine and confirm no leaks are present.

The engine mounted filter housing is equipped with a No-Filter-No-Run (NFNR)

feature. Engine will not run if:

1. No filter is installed.

2. Inferior/Non-approved filter is used. Use of OEM filter is required to ensure vehicle will run.

CAUTION!

•Diesel fuel will damage blacktop paving surfaces. Drain the filter into an appro-

priate container.

•Do not prefill the fuel filter when installing a new fuel filter. There is a possibility

debris could be introduced into the fuel filter during this action. It is best to install

the filter dry and allow the in-tank lift pump to prime the fuel system.

• If the “Water In Fuel Indicator Light” remains on, DO NOT START the enginebefore you drain water from the fuel filter to avoid engine damage.

6.7L CUMMINS® DIESEL

159

Page 162 of 252

UNDERBODY MOUNTED FUEL FILTER/WATER SEPARATOR

Draining Fuel/Water Separator

•If the “Water in Fuel” indicator lightis illuminated and an audible chime is

heard five times, you should stop the engine and drain the water from the separator.

• The drain is located on the bottom of the Fuel Filter and Water Separator assembly which is located in front of the rear axle above the drive shaft on pick up models.

The Chassis Cab models second filter location is on the frame behind the front

axle. The best access to this water drain valve is from under the vehicle.

• Turn the drain valve (located on the side of the filter) counterclockwise 1 full turn, then turn the ignition switch to the ON/RUN position to allow any accumulated

water to drain.

• When clean fuel is visible, close the drain and switch the ignition to OFF.

• Refer to the Diesel Supplement on the DVD for further details.

Underbody Fuel Filter Replacement

• With the engine off and a drain pan under the fuel filter drain hose, open the water drain valve 1 full turn counterclockwise and completely drain fuel and water into

the approved container.

• Close the water drain valve and remove the lid using a socket or strap wrench; rotate counterclockwise for removal. Remove the used o-ring and discard it.

• Remove the used filter cartridge from the housing and dispose of according to your local regulations.

• Wipe clean the sealing surfaces of the lid and housing and install the new o-ring into ring groove on the filter housing and lubricate with clean engine oil.

• Install a new filter in the housing. Push down on the cartridge to ensure it is properly seated. Do not pre-fill the filter housing with fuel.

• Start the engine and confirm no leaks are present.

The underbody mounted filter housing will cause the engine not to run if:

1. No filter is installed.

NOTE:

• Using a fuel filter that does not meet the manufacturer's filtration and water separating requirements can severely impact fuel system life and reliability.

• The WIF sensor is re-usable. Service kit comes with new o-ring for filter canister and WIF sensor.

6.7L CUMMINS® DIESEL

160

Page 173 of 252

WARNING!

A hot engine cooling system is dangerous. You or others could be badly burned by

steam or boiling coolant.

BRAKE- Brake Warning Light

This light monitors various brake functions, including brake fluid level and parking

brake application. If the brake light turns on it may indicate that the parking brake is

applied, that the brake fluid level is low, or that there is a problem with the anti-lock

brake system reservoir.

If the light remains on when the parking brake has been disengaged, and the fluid

level is at the full mark on the master cylinder reservoir, it indicates a possible brake

hydraulic system malfunction or that a problem with the Brake Booster has been

detected by the Anti-Lock Brake System (ABS)/Electronic Stability Control (ESC)

system. In this case, the light will remain on until the condition has been corrected.

If the problem is related to the brake booster, the ABS pump will run when applying

the brake and a brake pedal pulsation may be felt during each stop.

The dual brake system provides a reserve braking capacity in the event of a failure to

a portion of the hydraulic system. A leak in either half of the dual brake system is

indicated by the Brake Warning Light, which will turn on when the brake fluid level

in the master cylinder has dropped below a specified level. The light will remain on

until the cause is corrected.

Vehicles equipped with the Anti-Lock Brake System (ABS), are also equipped with

Electronic Brake Force Distribution (EBD). In the event of an EBD failure, the Brake

Warning Light will turn on along with the ABS Light. Immediate repair to the ABS

system is required.

Operation of the Brake Warning Light can be checked by turning the ignition switch

from the OFF position to the ON/RUN position. The light should illuminate for

approximately two seconds. The light should then turn off unless the parking brake

is applied or a brake fault is detected. If the light does not illuminate, have the light

inspected by an authorized dealer.

The light also will turn on when the parking brake is applied with the ignition switch

in the ON/RUN position.

NOTE:

This light shows only that the parking brake is applied. It does not show the degree

of brake application.

WARNING!

Driving a vehicle with the red brake light on is dangerous. Part of the brake system

may have failed. It will take longer to stop the vehicle. You could have a collision.

Have the vehicle checked immediately.

WHAT TO DO IN EMERGENCIES

171